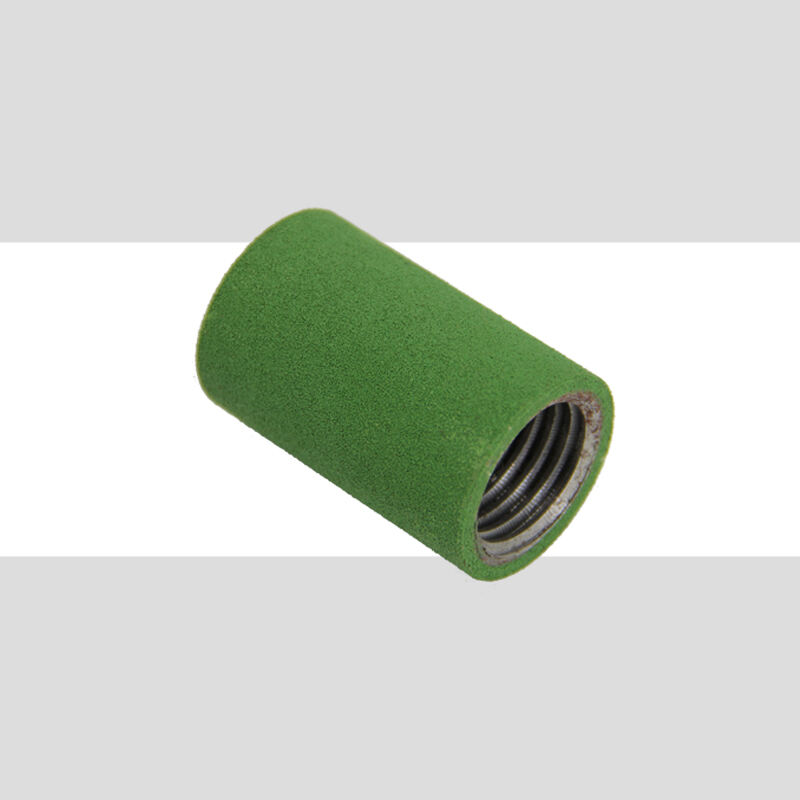

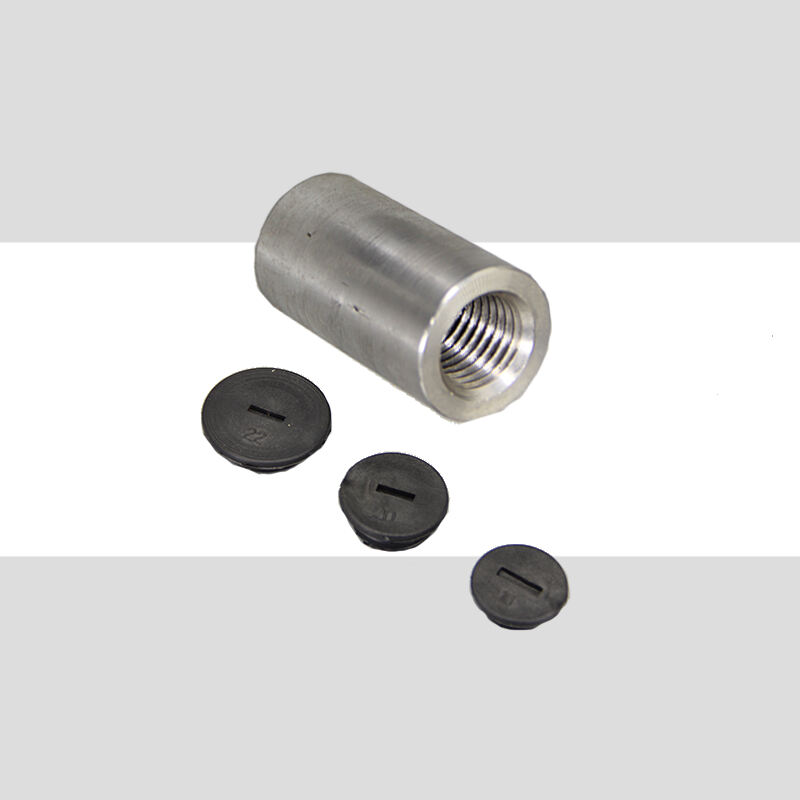

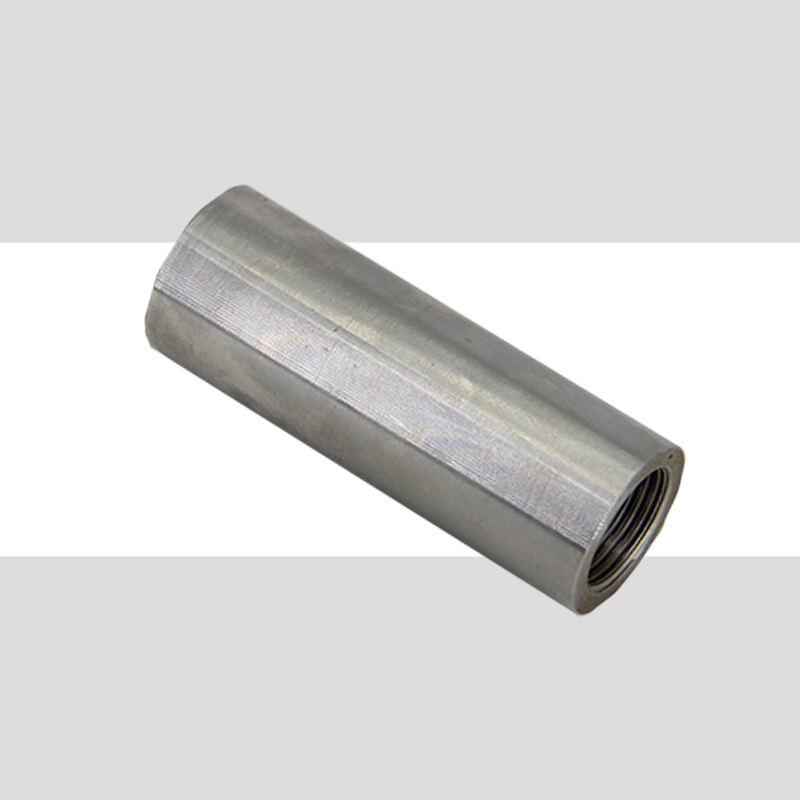

Super strength Cold Extrusion Press Coupler

This is a connection method that does not require preparation of the steel bar ends.

*Rebar connection range: from 12mm to 40mm, equal to #4 to #12 British rebar size.

- Overview

- Related Products

- Suitable for repair or reform projects

- Suitable for any rebar ends which are cold cut

- No reducing the cross section area of rebar

- All couplers have individual marks and batch numbers, so it is easy to trace raw materials. Totally produced in accordance with ISO 9001 standard.

Features:

Cold extrusion press system is a kind of flexible connection designed according to construction site. It is an easy operated method to connect rebar, no need to precast rebar in factory.

The swaging rebar splice is extruded on rebar ends with the pressure of high pressure device. The test result of this kind of connection can guarantee the tensile strength of connection specimen is no less than 125% of the normal yield strength of rebar. (rebar grade: 500MPa)

Cold extrusion press system is butt-to-butt connection which is suitable for applications that have both tension and compression requirements.

Advantages:

Installation guide

1. Site preparation work: clean and straighten rebar.

2. Mark on rebar half length of the coupler.

3. Put the coupler in the gauge length to limit the extrusion area, and then mark on both ends of cold extrusion press coupler.

4. We can’t extrude coupler outside the marking area after marking. We should extrude the coupler from middle to both sides.

5. Prepare hydraulic tools and install the corresponding pressure moulds. Prepare pump to connect power. If the motor is 380V or 440V, please rotate the switch to correct motor first.

6. Insert half length of the coupler onto rebar, connect according to indicating mark.

7. Extrude coupler with required pressure.

8. Stop extruding when it reaches the pressure value of specified size.

9. The process above is repeated many times according to each size requirements.

10. Prepare as many rebar end as need to connect.

11. Insert the rebar need to connect into the coupler extruded on the first rebar.

12. Repeat the extrusion process on the connecting rebar.

Application projects

Our products can applied to bridge rebar splice, Nuclear power engineering rebar splice, Seawater desalination rebar connection, LNG project rebar splice, Metro rebar connection, High tower rebar connection, Viaduct rebar connection and etc.

Product parameters:

The Parameter For Standard Rebar Coupler(MM) | ||

Steel bar Diameter(MM) |

Out Dia.of Coupler(MM) |

Length of Coupler(MM) |

16 |

30 |

130 |

18 |

34 |

130 |

20 |

36 |

150 |

22 |

40 |

132 |

25 |

45 |

150 |

28 |

50 |

168 |

32 |

56 |

192 |

36 |

63 |

216 |

40 |

70 |

240 |