- Overview

- Related Products

Steps

1.Cold forging

The sawn end of rebar is enlarged by a patented cold forging process, the core diameter of the bar is increased to a pre-determined diameter

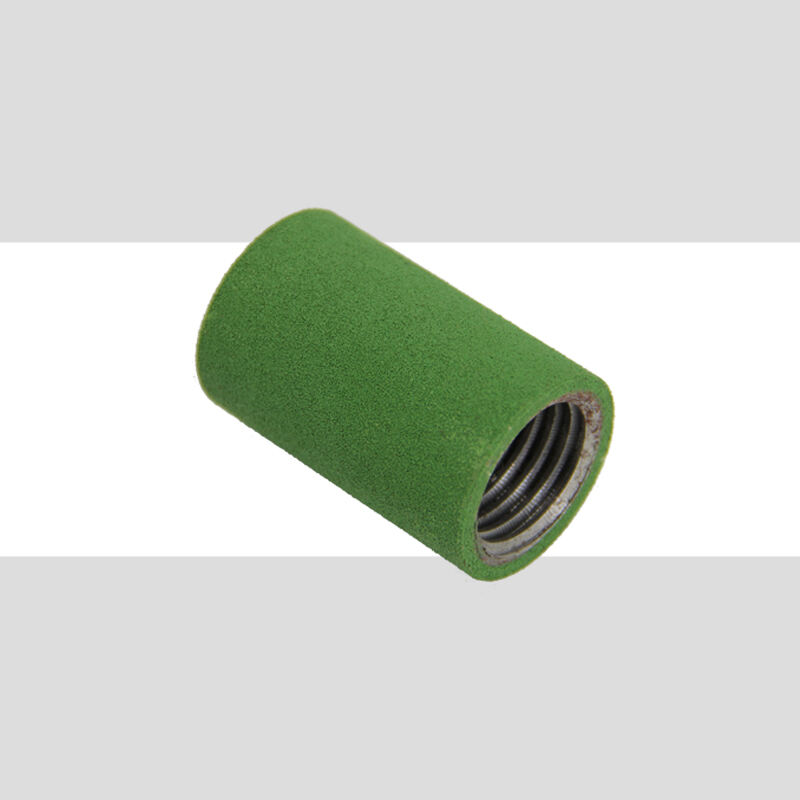

2.Make thread on the ends of rebar , one thread is addling length , the other thread is the standard length.

3.Screw the full coupler onto rebar end with adding length thread

4.Finish the connection by screw back the coupler to the second bar.

* Upset forging the end of bar play the role of a mechanical extrusion , so the molecular structure is tighter , strength surpass the parent bar, increase the strength value in the tensile.

*The thread cross section area after cold forging is not less than parent bar , the area with thrust surface is larger or equal to the parent bar during the tensile test , so the strength of larger than parent bar.

Upset forging parallel thread connection is the best accepted connection way in the world, also the highest quality connection technology in rebar mechanical splicing, 100% higher than 1.1 to 1.3 times of parent rebar, bear the ultimate test 100% break on the bar outside coupler.

Please kindly find small video , the demo of rebar cage , showed by our international sales person